Csplast has been designing and producing technical components and articles in rubber and plastic on commission for all industrial sectors for over 40 years. This is why we understand the main requirements requested in this sector: plastic articles must be effective and functional, long-lasting, easy to install and cheap.

Our huge experience allows us to achieve the best solutions for each sector of competence, providing technical solutions which lead to excellent component efficiency, both from a performance and economical point of view.

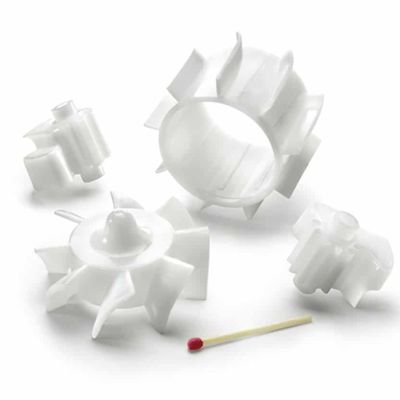

One of the specializations that we deal with most frequently within the technical sector is that relating to the design and production of mechanical components. These details represent a very important and highly valuable sector for Csplast and they can vary from simple technical parts to complex systems.

Our great experience, our polymers knowledge (from the common ones to the super-polymer ones) and our constant research and development activities linked to the application of industrial plastics allow us to satisfy every technical and mechanical requirement.

When the technical articles to be designed are for installation in complex mechanical systems, we carry out feasibility studies and structural FEM (finite element method) analysis which gives us useful information on any deformation, stress or movements which may occur on plastic components so as to optimize engineering of the pieces. Whenever our reference is an object which already exists, we apply reverse engineering to digitalize physical objects so that the geometric surfaces can be analysed and remodelled on a computer.

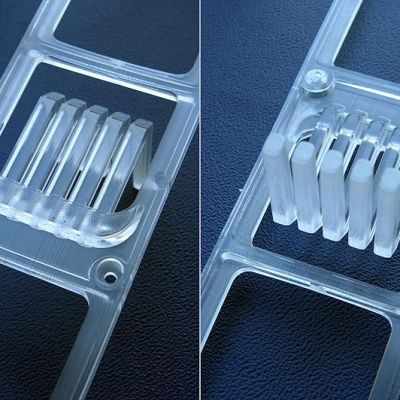

Metal – plastic conversion

The activity we most frequently perform in this sector is the conversion of metal products into plastic ones: thanks to our many years of experience, our deep understanding of polymers (from the most common ones to super-polymers), together with our constant research and development activities within the scope of industrial plastic applications and the use of avant garde and innovative technologies, we can carry out feasibility studies on the possibility of transforming components traditionally made from metal into plastic components with the same characteristics and functions.

The reproduction of a product in plastic represents a choice in favour of technological innovation which can bring with it numerous benefits, such as:

- Speed of components assembly thanks to the use of interlocking parts and hooks which replace the use of fasteners

- Lower maintenance costs

- Reductions in transport and installation costs, thanks to the reduced weight of the components

- Better aesthetics

- Enviromental impact reductions, for example by eliminating the need to use toxic paints previously used for sheet metal parts

Our experience in the engineering of technical articles has allowed us to create components for many industrial sectors, such as gears, wheels, couplings, cap seals, inserts, valves, seals, spacers, etc.

- Components for the mechanical sector

- Components for the system engineering sector

- Automotive components

- Articles for the food industry

- Articles for the building sector

- Articles for the agricultural sector

- Articles for the aerospace sector

- Articles for the cosmetics sector