THE CHALLENGE

MARSS IP & Security Srl (More Advanced Research in Security System) is a leading Italian company which develops innovative and unique solutions for technologies and applications used in the security, video surveillance and home automation sectors. Its corporate philosophy is based on continual evolution and the search for new solutions for the security sector.

This propensity for technical and qualitative innovation is what made Marss turn to our Csplast team to create new equipment which enables the user to activate remote security management within the field of home automation: the IP Controller.

The challenge we were set was to develop a new simple and modular product with an eye-catching design which could incorporate: functionality, style and simplicity of use. Furthermore, due to the ever-changing nature of the electronics market, it was also essential to consider the need to complete the project in as short a time as possible.

THE SOLUTION

Design

After the first briefing between our technical staff and the client, work began with the development of an electronic equipment design. The lines and geometry were conceived so as to keep all the internal components in a functional manner, without overlooking the need to give the product a look conveying technological innovation, needed to distinguish the product on the market

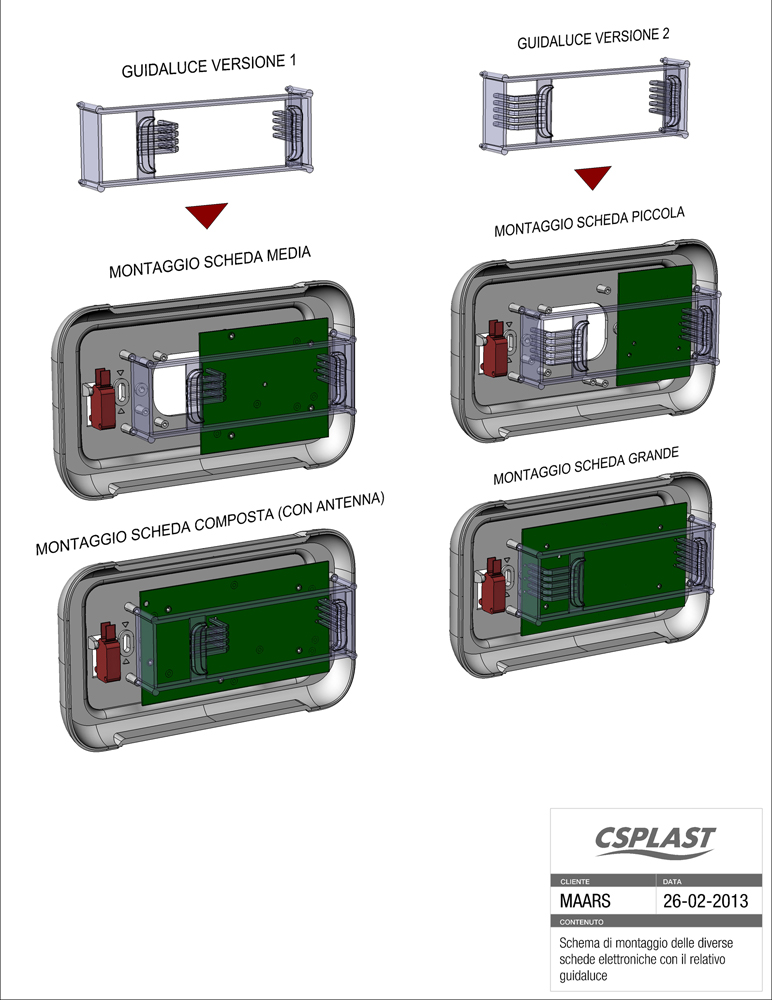

The initial stage involved considering the functional requirements and the interior component dimensions, such as two interchangeable electronic boards which must be indiscriminately installable inside the housing and the need to insert a light beam guide to convey the light produced by the LEDs.

Engineering

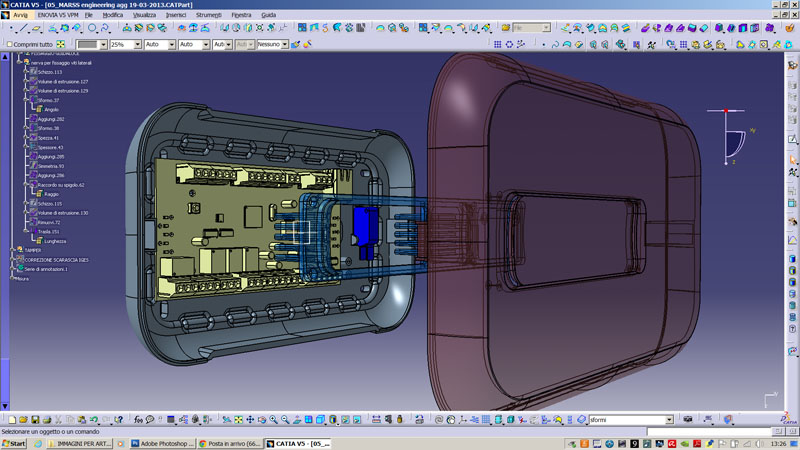

Once the first photorealistic renderings of the IP controller had been developed, Csplast went on with the stage to engineer the virtual 3D model in order to establish all the shape and structural details of the product. Connectors and thicknesses were defined by our design engineers in order to observe the design requirements and the restrictions linked to moulding issues and the physical making of the mould, without ever overlooking the physical characteristics of the ABS material to be used to manufacture the casing. To simplify the assembly operations we opted for interlocking shells, thus excluding the use of screws. The external surfaces of the virtual models of the two shells were defined together with the details of their structure, making the geometry compatible with the dimensions of the electronic boards to be housed inside.

Prototype

In order to give our clients the chance to test the product on the market and give them the possibility of performing technical checks on the actual product, we made a physical prototype of the various assembly components using rapid stereolithography prototyping technology. In this way the client had the opportunity to see the geometrical shape of every detail and the functionality of the overall article before proceeding with the production phase for creating the moulds.

Injection mould Engineering

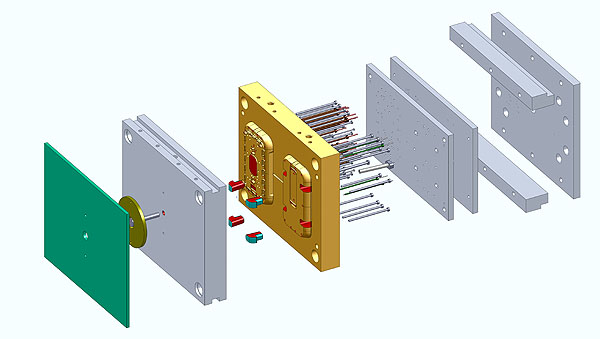

The meticulous and close collaboration between the design and engineering operations made it possible for our staff to design a product which was completely free from undercuts and therefore optimize, from a costs and times point of view, the fabrication of the injection moulds.

Injection Mould Construction

Made from hardened steel in the CSPLAST workshop, the moulds for the casings and the light guide were immediately used to carry out the moulding of the pre-series articles, useful for final testing, which was followed immediately after with mass production for the client’s end market.

RISULTATO

Csplast, by accompanying the client from the development of the product concept up to its mass production made it possible to reach the goals Marss had set itself to manufacture the IP controller module in a really short time. A personalized product with a minimalistic and innovative line, with a unique look for this kind of object, adaptable to different types of electronics, easy to assemble and install and with low production costs.

- IP CONTROLLER DESIGN

- ENGINEERING

- PROJECT – ASSEMBLY SCHEME

- INJECTION MOULD PROJECT

- INJECTION MOULD CONSTRUCTION

- IP CONTROLLER – MOULDED PIECE

- SCHELLS AND LIGHTGUIDE

- PAD PRINTING