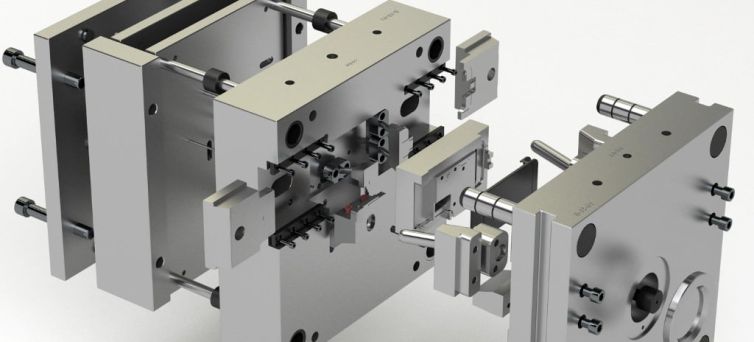

Csplast has the very latest in software and hardware equipment as well as avant garde CAD tools for engineering pieces and then developing the injection moulds.

Our highly-qualified technicians are able to design moulds for products of the highest technical and aesthetic quality for a lot of sectors, like the food processing equipment and the horeca/vending (production of technical articles and mechanical components where metal-plastic conversion represents an innovative choice) and the safety, medical, automotive and industrial instrumentation sectors (production of handheld computers and plastic containers for electronic cards ).

Our forty years of experience allows us to create or assess any project for the purpose of analysing the costs to construct equipment (mould construction for plastic materials) and any margins for improvement or simplification (also to achieve possible savings).

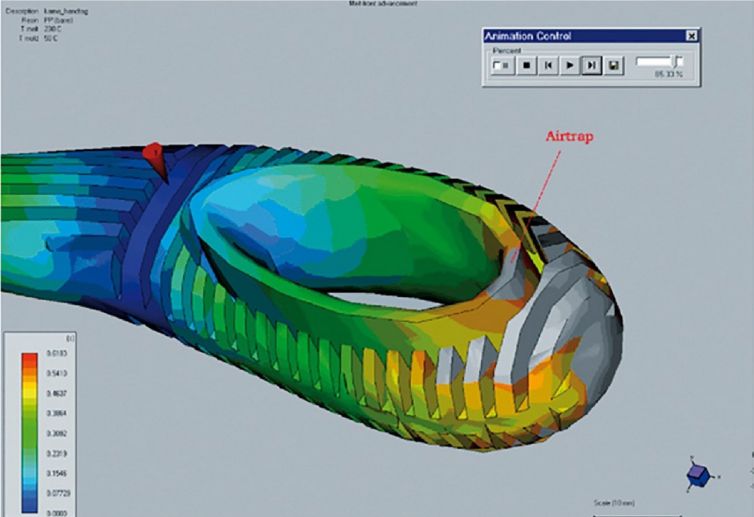

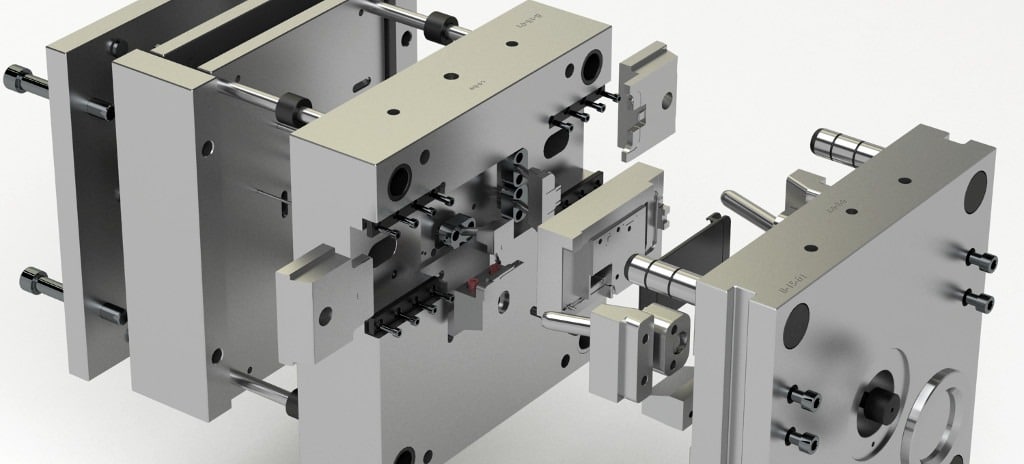

Our injection mould engineering department provides projects which can be immediately executed and free from any construction or functional issues.

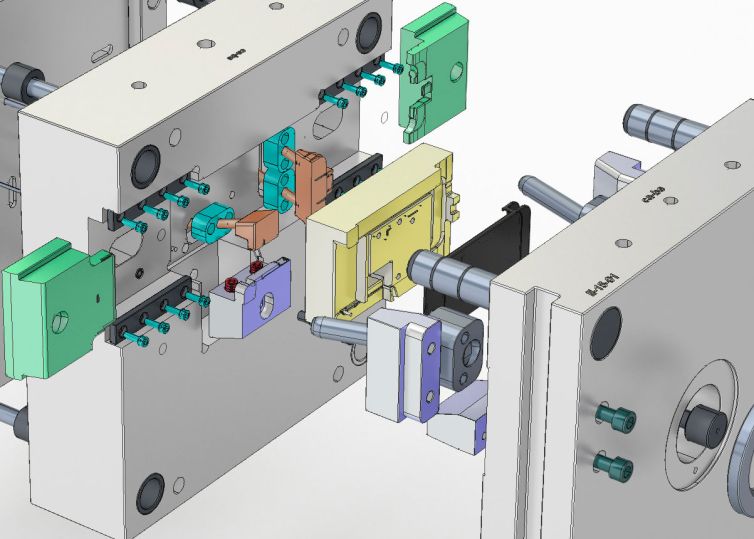

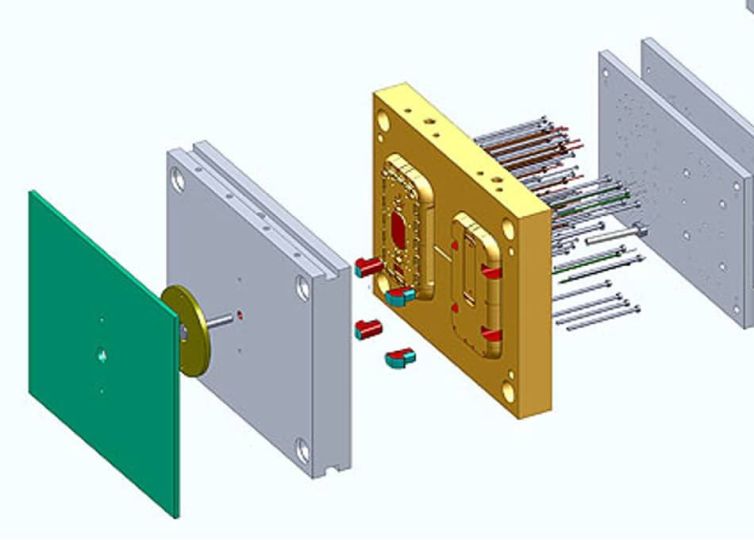

Our know-how allows us to identify the best technical and construction techniques for creating the injection moulds, such as:

- TYPE OF STEEL

- INJECTION SYSTEMS

- EXTRACTION SYSTEMS

- TEMPERATURE CONTROL SYSTEMS

- SLIDING PART

- HEAT TREATMENTS

- SURFACE FINISHES