Redesigning a metal product in plastic helps to:

Increase efficiency and sturdiness;

Speed up assembly operations with significant reductions in maintenance costs;

Improve the appearence;

Achieve a significant reduction in the enviromental impact.

MEAT HOOK

This meat hook, which used to be made from shaped and welded stainless steel, is now manufactured using glass fibre-reinforced PA. It is much lighter, production times are reduced 50:1 and costs are equally reduced.

The material is recyclable and its food-contact conformity is certified.

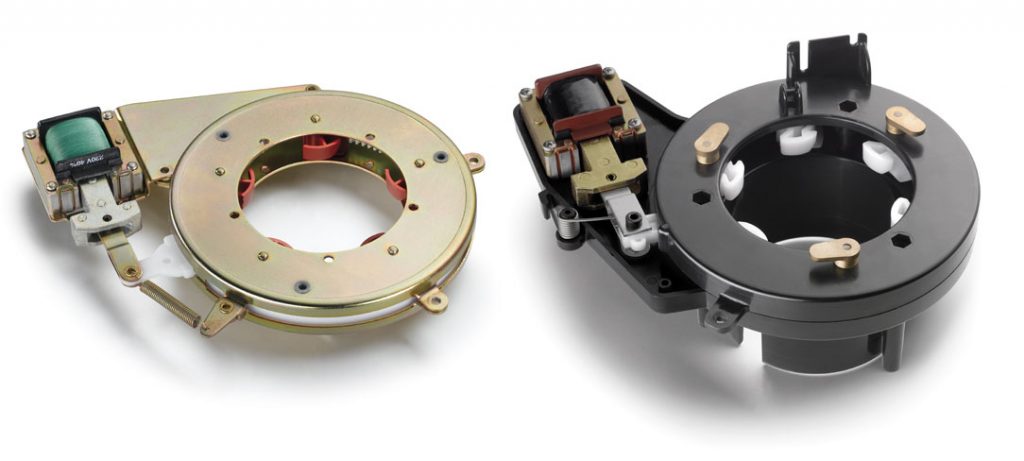

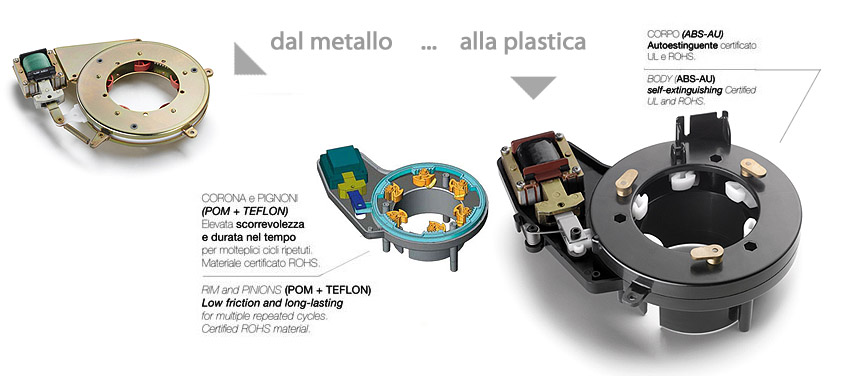

CUP DISPENSER

This cup dispenser used to be made with mechanical technology from shaped, welded and painted sheet metal. The components were assembled and fastened using screws.

PlastDesignStudio redesigned it in plastic and optimized it for injection moulding production.

Eliminating all the parts in sheet metal resulted in optimization of assembly by means of interlocking parts, simplification of installation and maintenance, reductions in weight and noise emissions during operation.

The product turned out to be more eco-friendly thanks to the lack of paints used and the fully recyclable nature of the plastic components.