THE CHALLENGE

A medical equipment company came to PlastDesigStudio, considering us a supplier which could accompany it in the conception and realization of a new medical handpiece for physiotherapy and cosmetic treatments.

The company, which has been operating in the medical sector for many years possesses a great deal of know-how in the engineering and construction of electronic products used in physiotherapy and electromedical treatments and is constantly looking for advanced technologies in order to be able to present state-of-the-arts machinery on the market. To develop the new handpiece they asked us to guide them through the development of the casings and the plastic components, setting out some essential targets: aesthetics, quality, ergonomics and ease of use.

THE SOLUTION

Design and engineering

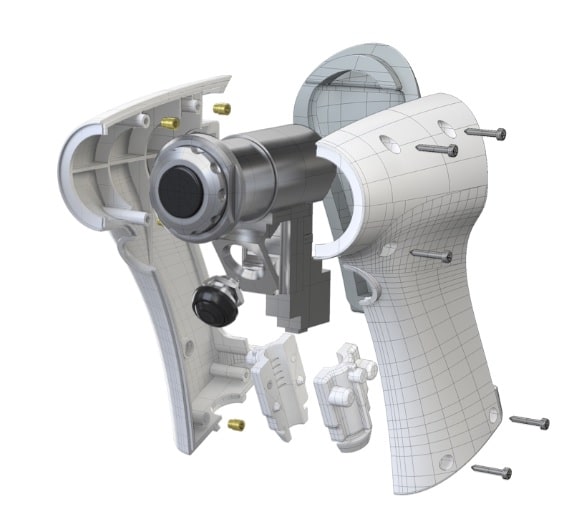

At the first meeting between the company and our product designers, we were given a graphic sketch of the article the client wanted to make: a gun-shaped handpiece which, when connected to a medical device, delivers acoustic waves for physiotherapy and cosmetic treatments. This handpiece, characterized by a structure with a metallic base, needed to be completed with a hand grip and a series of other plastic accessories.

Based on our design and production experience in the medical sector and by discussing the needs expressed by the client, our design engineers identified certain fundamental and essential project requirements:

- cleaning: the plastic sections had to be without slits or any other openings or grooves which could trap dirt. In fact, the handpiece glides over the patient’s body thanks to conductive gel which must be easy to remove without leaving any difficult-to-reach areas.

- comfort of use: each time the handpiece is used by the healthcare professional it begins to emit acoustic waves (used to treat the patient) by means of vibrations. If the handpiece is used for a prolonged period of time, the vibrations felt by the operator make use of the appliance unpleasant. This is why we proposed to make part of the hand grip using rubber so as to increase the feeling of comfort and to give a softer support for the user.

- focus on product aesthetics and look: for an article used in well-being facilities and clinics the look and image the product gives to the client and end user must never be overlooked. This is why we put a lot of care into the lines of the handpiece, the selection of materials to achieve better aesthetics and the positioning of edgings designed to hide any imperfections along the casing closure lines which during moulding could have slightly different sizes.

During the engineering and realization of the object’s 3D mathematics, we paid particular attention to those points which had to be sturdy, ensuring the right thicknesses and reinforcement where needed, for example the crown at the end of the handpiece, on which the operator exercises constant pressure, and at the base of the hand grip, to facilitate the passage of the power cable.

At the end of the engineering phase, the appliance was made up of two half-shells, a cable gland, a crown support and a support pad made from soft rubber which coupled with the interlocking plastic parts.

Prototype

Once the three-dimensional geometries of the plastic components had been optimized, we made, at the client’s request, a nylon and Duraflex prototype so that the product could be properly tested before proceeding to engineer and build the injection moulds.

Mould engineering and construction

Once the client company had approved the prototype and excluded the need for any modifications to the project, we continued to develop the product by proceeding to engineer the moulds: one to make the plastic parts and one for the rubber support pad. For the latter, in particular, samplings with different materials were carried out so that our client could identify the rubber with the best performance in terms of aesthetics, comfort and touch/feel.

RESULT

Having taken into consideration, right from the design stage, the importance of the aesthetic and functional aspects of the product, the choice of the most suitable moulding materials for minimizing vibrations and keeping to the ergonomic and cleaning objectives, meant that Csplast, (to whom the creation of the moulds was assigned) did not encounter any of those construction difficulties which often occur when there has been discontinuity in the design stages.

A medical device of great technical efficiency with a high aesthetic impact was created, the qualities of which were soon recognized and appreciated on the reference market.